Improving Lab Training & Student Engagement Through VR

Student Engagement

An immersive approach to virtual labs ,Randomized controlled trial (RCT) based evaluation,Innovative authoring software for immersive training

Objective

Reduce student errors and safety risks

Increase student engagement

Improve learning outcomes

Overview

This project was aimed at improving lab training while reducing the overall cost and safety risks for students in mechanical engineering laboratory classes. HyperSkill was used to show the feasibility of enabling non-programmers to create high quality VR based training simulations.

Key Features

- Immersive experience

- Incorporating physics of material behavior

- Conversational AI

Challenges

Student errors can cause damage to expensive machines resulting in tens of thousands of dollars in repair costs as well as significant downtime and lab scheduling disruptions.

The tension test was selected due to the high equipment cost and inherent safety risks involved in high tension material testing.

TAMU faculty were looking for ways to improve lab training while reducing the overall cost and safety risks. The requirements were specific:

- Eliminating the safety risks, equipment availability bottlenecks and costly damage risks

- Increase student engagement

- Improve learning outcomes

The Solution

SimInsights teamed up with TAMU and Instron and began work on the following fronts:

- An immersive approach to virtual labs – with an emphasis on providing engagement and experiential learning

- Randomized controlled trial (RCT) based evaluation – which aims to rigorously assess the impact of interventions in human subject studies

- Innovative authoring software for immersive training – called HyperSkill to enable faculty and other subject matter experts to create their own immersive content.

The Design

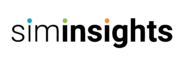

HyperSkill was used to create most of the tensile test simulation shown in Figure 1 except the specimen deformation and stresses which were computed using Abaqus finite element analysis (FEA) simulation software from Dassault Systemes, and imported into HyperSkill.

Pilot testing was conducted at Texas A&M University.

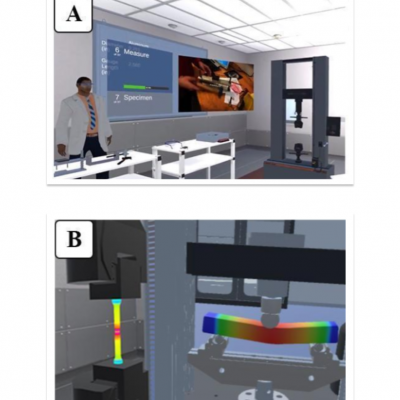

- - A two-group, randomized control trial was conducted as part of a course with a total of 118 students.

- - 57 participants were assigned to the control condition (Instron machine is used first, followed by VR) and 61 to the experimental condition (VR first, then Instron).

- - Results of the pilot test suggested an overall positive outcome for students participating in the VR virtual lab first (experimental condition) compared to those who performed the physical lab first (control condition).

Delivery : SimInsights VR system integration

Three VR systems were set up in a separate room in the engineering building (see Figure 2 below). Instructors from different classes were able to reserve the room for their students. Students could access the room at their own convenience, log in and experience the VR simulations as many times as needed. The data could be collected and shared with the relevant instructors. Beside the initial materials course, additional faculty have used the set up for their courses including Industrial Engineering, Chemical Engineering and Engineering Design.

Measurable Benefits

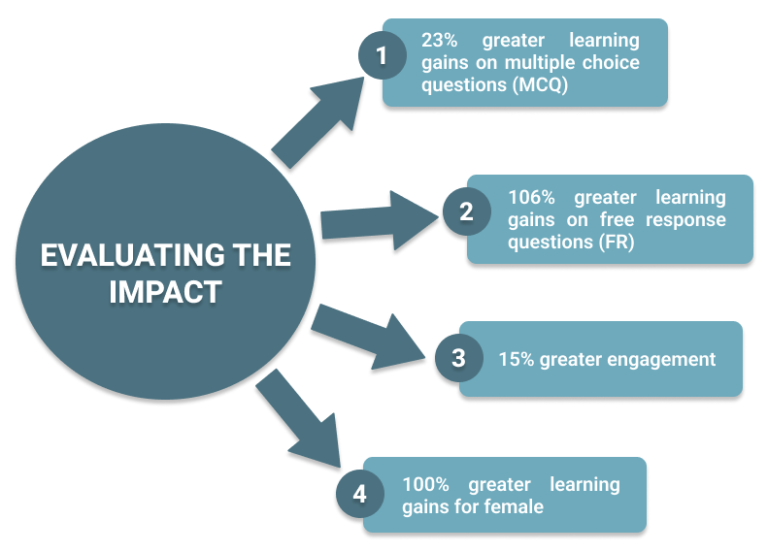

Analysis of pilot test data (survey measures, action and sensor data) from 118 students revealed the following highlights:

- - 23% greater learning gains on multiple choice questions (MCQ) – Students who participated in the VR activity first scored 23% higher on MCQ subject matter scores, including 5% higher procedural subscale and 49% higher conceptual subscales scores.

- - 106% greater learning gains on free response questions (FR) – Analysis of pre-post gain indicated significantly higher gains for participants in the VR activity compared to the Instron activity.

- - 15% greater engagement – Additionally, students reported significantly higher engagement after the VR activity than after the physical lab.

- - 100% greater learning gains for female participants – Subgroup analysis of pre-post learning gains indicated that females in the experimental group gained twice as much over males.

Success Factors

There were four key factors that contributed to the success of the project.

Success Factor #1: Content first

The SimInsights team delivered on this requirement by matching the realism of the interactions and exceeding the richness of the learning by using nonlinear finite element analysis (FEA) simulation to visualize the physics of material testing.

Success Factor #2: Data driven

Starting with the early usability studies conducted with TAMU students, SimInsights followed data to drive prioritization and design of the software features and functionalities.

Success Factor #3: Conversational AI

Conversational AI has always been a key element of our VR experience design strategy. Students loved it from the very beginning, providing valuable feedback to drive refinements, and challenging the team to support increasingly complex and meaningful queries.

Success Factor #4: Partnering with the experts

The most important success factor was recognizing the importance of partnering with experts early on, scheduling weekly meetings with key faculty and even teaching assistants. This enabled our team to produce content that addressed key learning and assessment objectives, without resources.

Testimonials

- - Dinakar S., Assistant Professor, Industrial Engineering, Texas A&M University said “I have been using the HyperSkill CNC machining simulation in my courses in Industrial engineering at Texas A&M for the last couple of years. It is both an engaging experience for students as well as offers substantial educational value for the targeted content. Furthermore, the VR simulation is a nice tool to get students thinking about innovative applications of this exciting technology in other domains.”

- - Joseph Kwon, Assistant Professor, Chemical Engineering, Texas A&M University said “I have been developing a chemical plant control VR simulation for use in my courses in Chemical Engineering at Texas A&M and it has been a pleasure to work with the SimInsights team and their software platform. VR has tremendous potential for the future of education. “

- - William Predebon, Professor and J. S. Endowed Chair of Mechanical Engineering-Engineering Mechanics, Michigan Technological University said “Our faculty have been developing VR and AR content for use in our mechanical engineering courses at Michigan Tech and it has been a pleasure to work with the SimInsights team and their software platform. VR/AR technology has tremendous potential for the future of education and research.”

- - Britt Smallwood, Business Unit Manager, High force applications, Instron said “It was my pleasure to support this project by SimInsights from the Instron side. We provided CAD models and technical information which enabled SimInsights to create a realistic virtual simulation of the Instron machines. Later the team visited our headquarters in Massachusetts to demonstrate their solutions. This technology has a promising future for training and sales purposes.”

Read the full case study

Testimonials

Dinakar S., Assistant Professor, Industrial Engineering, Texas A&M University said “I have been using the HyperSkill CNC machining simulation in my courses in Industrial engineering at Texas A&M for the last couple of years. It is both an engaging experience for students as well as offers substantial educational value for the targeted content. Furthermore, the VR simulation is a nice tool to get students thinking about innovative applications of this exciting technology in other domains.”

Joseph Kwon, Assistant Professor, Chemical Engineering, Texas A&M University said “I have been developing a chemical plant control VR simulation for use in my courses in Chemical Engineering at Texas A&M and it has been a pleasure to work with the SimInsights team and their software platform. VR has tremendous potential for the future of education. “

William Predebon, Professor and J. S. Endowed Chair of Mechanical Engineering-Engineering Mechanics, Michigan Technological University said “Our faculty have been developing VR and AR content for use in our mechanical engineering courses at Michigan Tech and it has been a pleasure to work with the SimInsights team and their software platform. VR/AR technology has tremendous potential for the future of education and research.”

- Britt Smallwood, Business Unit Manager, High force applications, Instron said “It was my pleasure to support this project by SimInsights from the Instron side. We provided CAD models and technical information which enabled SimInsights to create a realistic virtual simulation of the Instron machines. Later the team visited our headquarters in Massachusetts to demonstrate their solutions. This technology has a promising future for training and sales purposes.”