VR and ar enabled manufacturing training

VR and AR

Providing students with VR & AR enabled personalized manufacturing training

Objective

As described in the recent US council report on competitiveness, advanced manufacturing has the largest multiplier effect on jobs. In order for the US to gain competitiveness in this sector, there is a pressing need for a trained workforce that is able to develop new materials testing protocols and manufacturing processes. The educational sector (including universities and technical schools) needs to train students rapidly and effectively in these skills while also rapidly adapting to technological progress.

Overview

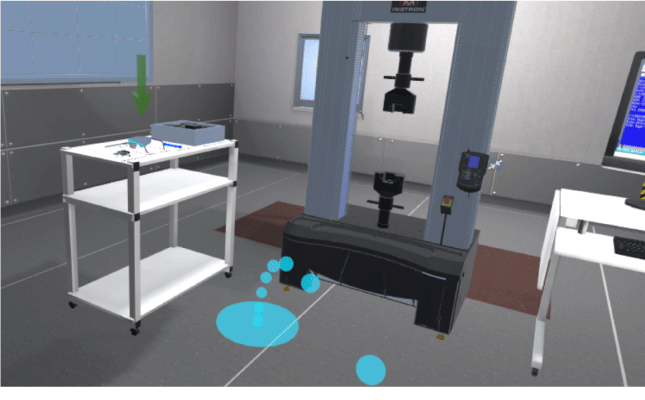

Providing students with Virtual Reality (VR) and Augmented Reality (AR) enabled personalized manufacturing training labs is a promising way to increase students’ engagement and better prepare them for future careers as well as broaden students’ outlook on innovation within a highly competitive high-tech driven economy as defined by the National Academy of Engineering Strategic Plan.

According to 2014 statistics, in the United States, less than 40% of students entering college in STEM fields finish with a STEM degree. And even for those who finish, a majority (over 60% ) take several years longer than the nominal time of 4 years to finish an engineering degree. As the need for STEM graduates is higher than ever, it is necessary to accelerate the progress toward graduation so that the limited educational resources can be utilized more effectively. Simultaneously, it is important to equip students who are interested in these fields with the attitudes and skills they need to thrive in a changing technology landscape.

Traditional lab education versus proposed approach

- Traditionally, the bulk of materials testing training has been carried out in a hands-on manner in laboratories and machine shops. Typically the number of students reached is small due to both the time required for training as well as safety requirements, limiting the utilization of capital intensive equipment. Furthermore, given the requirements of advanced manufacturing, the hands on training needs to be supplemented with extensive classroom teaching to help students understand the mechanisms and causes for the materials science phenomena.

- VLab is a software product for efficient creation of innovative content for use on a range of VR and AR devices. Specifically, VLab supports creation of equipment focused content and analytics. We are applying VLab to create innovative content for use in materials testing courses at one of the largest US university, in collaboration with an industry leading equipment manufacturer. By judiciously combining virtual objects with hands on activities, we aim to dissolve the boundary between classroom education and hands-on training, providing an effective and seamless educational experience for materials testing and manufacturing training.

Benefits

- Immersive and engaging learning experience.

- Combine procedural and conceptual learning and assessment.

- Content portable across VR and AR platforms.

- Ease of content creation, modification and sharing.

- Voice based interaction for ease of use and engagement.

- Dashboard for data driven decisions.

FEATURES

- Support for HTC Vive, Microsoft Hololens and mobile VR/AR platforms.

- Rich data visualizations for decision support.

- Integration of nonlinear finite element simulation with the 3D game like experience.